Key features

Plug & Play oxygen generator compact, mobile and silent 10 to 20l / min flow at 3.8 ba Integrated PSA columns Integrated oxygen analyzer Fully automatic. fully digitalize can be monitor by every screen.

High purity Systems

PSA Oxygen generators are typically used in applications where the purity requirement is higher 95% (0.5% O2 or below). Depending on the customer's requirements

Lowest Maintenance

Maintenance is easy as well. You will only be required to change the filters. operating Valves every Year. PSA Oxygen Generator is simple too – just start up the PSA Oxygen generators by a switch and

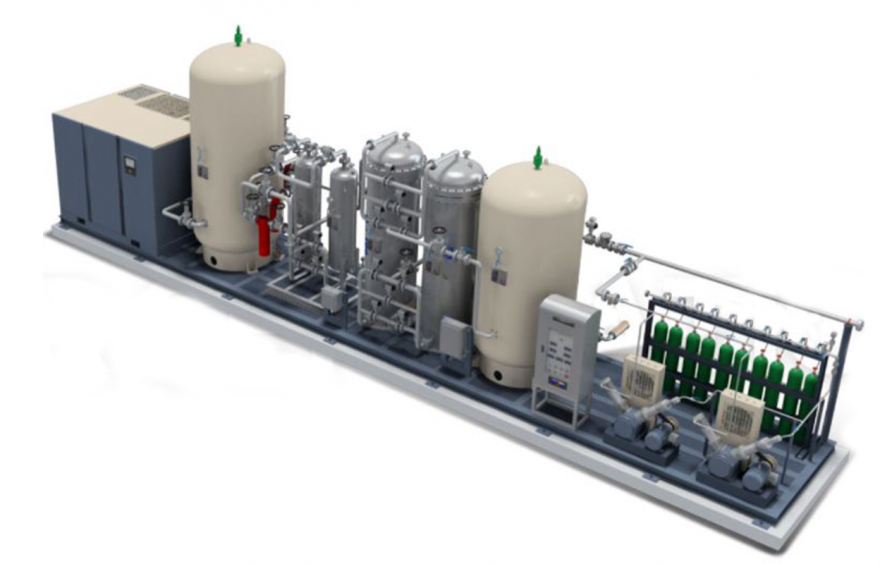

Oxygen Generator PSA System

Oxygen PSA Generator process In 5 main stages: Compressed air (78% nitrogen, 21% oxygen, < 1% argon) is filtered, degreased and dried and the production pressure is automatically regulated. Air passes through the molecular sieves where nitrogen is adsorbed by the zeolite, increasing oxygen concentration up to 95%. Out of the molecular sieve, the oxygen produced is sent through the buffer tank via a mutifunction block. Nitrogen is released via a silent escape and forced back outside. Part of the oxygen produced is used to help the nitrogen desorption of one vessel while the other ensures oxygen production (and vice versa). An automatic and pneumatic vessels balance system ensure a continuous oxygen flow. A solid state programmable controller operates the process valves on an alternating cycle, with built-in logic for automatic stop/start. Oxygen flow and purity remain constant regardless of the peak usage demands

Application

Hospital, Fish Farm, Complete combustion, Ozone, Fermentation, Sewage treatment plant, cutting/brazing

• Air Compressor: Air compressor is the equipment to produce compressed air. Compressed air is used for separating oxygen from the air. In the process of compression, moisture and heat happen. To remove them, a built-in or independent air dryer and after-cooler are necessary

• Air receiver Tank: Air receiver tank is the equipment to keep supplying compressed air of certain pressure to the oxygen generator stably. It is also for the purpose of handling a load of the compressor properly.

• Filter: Filter is used for removing dust, particle, and oil in compressed air.

• Desiccant air dryer: This is used for removing moisture by using an adsorbent. It consists of two adsorbers and it has the repeated cycles of adsorption and regeneration

• PSA Generator: In order to separate the oxygen from the compressed air, ZMS(Zeolite Molecular Sieve) is used as an adsorbent. O2 PSA system consists of pressurization, production, purge, equilibrium of pressure, and regeneration.

• Oxygen storage Tank: It is a buffer (storage) tank to supply the processed oxygen with a certain pressure, purity, and flow.

• LCP: LCP has control of the whole system into operation automatically or manually. It also indicates purity, pressure, and flow of the produced oxygen..

• Oxygen supply: The purity of the produced oxygen is 90 ~ 95%. Flow and pressure depend on customer`s needs

• High-pressure Compressor: It is a high-pressure compressor to fill oxygen cylinders at 125~150BarG

• Manifold and Oxygen cylinder: Pipelines are designed to fill oxygen cylinders at the same time and cylinders are connected at the end of the manifold

O2 PSA TYPE

| MODEL | O2 FLOW (Nm3/H) | SIZE(W*D*H) | WEIGHT(kg) |

|---|---|---|---|

| 0-2 | 2 | 685*570*1566 | 390 |

| 0-3 | 3 | 800*640*1623 | 510 |

| 0-5 | 5 | 850*680*1966 | 710 |

| 0-8 | 8 | 1080*812*1863 | 940 |

| 0-10 | 10 | 1080*812*2192 | 1120 |

| 0-12 | 12 | 1230*920*2207 | 1260 |

| 0-15 | 15 | 1330*980*2270 | 1470 |

| 0-18 | 18 | 1621*1237*2664 | 1630 |

| 0-21 | 21 | 1621*1237*2820 | 1690 |

| 0-23 | 23 | 1821*1310*2823 | 2120 |

| 0-25 | 25 | 1821*1310*2909 | 2140 |

| 0-30 | 30 | 822*1361*2980 | 2620 |

| 0-35 | 35 | 2126*1513*2891 | 3020 |

| 0-40 | 40 | 2126*1513*3100 | 3400 |

| 0-45 | 45 | 2126*1513*3410 | 3670 |

| 0-50 | 50 | 2329*1615*3426 | 4420 |

| 0-60 | 60 | 2329*1816*3400 | 4700 |

| 0-70 | 70 | 2732*1816*3466 | 5440 |

| 0-100 | 100 | 3138*2019*3738 | 7130 |

| 0-120 | 120 | 3488*2194*4000 | 8100 |

| 0-140 | 140 | 3488*2194*4209 | 9330 |

Need a help?

Please Fill The Form Our Team Will Contact You As Soon As Possible.